What are the key points of quality control for welding column boom?

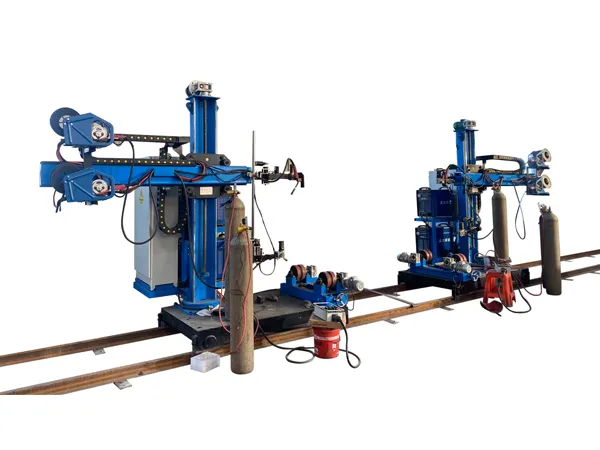

With the continuous development of modern industry, welding technology, as an important means of connecting metal structures, is increasingly used in the manufacturing industry. However, the quality control of welding column boom is particularly important to ensure the stability of the welding process and the quality of the welded joints, so as to ensure high energy efficiency and safety during the welding process.

Analysis of key points of quality control of welding column boom

1. Operator training and certification

In the quality control of welding column boom, the training and certification of operators are very important. Only welders who have undergone professional training and qualified certification can master the use skills of welding column boom and effectively deal with various complex situations. The training content includes welding principles, equipment operation, safety knowledge, etc., to ensure that the operators have comprehensive technical literacy.

2. Welding process specifications and parameter control

In the process of use, formulating scientific and reasonable welding process specifications is an important part of ensuring welding quality. The reasonable setting of parameters such as welding current, voltage, welding speed, and the formulation of process requirements such as preheating and post-weld treatment have a direct impact on the strength and stability of the welded joint. Accurately controlling these parameters can improve welding quality and reduce the occurrence of welding defects.

3. Welding material quality control

The quality control of welding column boom also requires strict quality inspection and control of welding materials. Including the inspection of welding materials such as welding wire, flux, and welding rod to ensure that they meet relevant standards and specifications. Qualified welding materials can not only improve the firmness of the welded joint, but also reduce the occurrence of defects such as pores and slag inclusions during the welding process.

4. Equipment maintenance and calibration

Equipment maintenance and calibration are key steps to ensure its normal operation and welding quality. Regularly maintain the welding machine, check the wear and damage of components such as welding power supply, electrode head, transmission system, etc., replace and repair them in time to ensure that the equipment is in good working condition. At the same time, regular calibration is performed to ensure the accuracy and stability of welding parameters.

…

For more detailed information on the key points of quality control of welding column boom, please click to visit: https://www.bota-weld.com/en/a/news/welding-column-boom-quality-control.html