Detailed explanation of vibrating screen exciter maintenance procedures and maintenance requirements

In the field of industrial equipment maintenance, as one of the key equipment, the vibrating screen exciter must follow a series of steps and standards during its maintenance process to ensure its reliability and durability. The maintenance process of the vibrating screen exciter includes a series of strict operations, from taking photos and archiving the original condition of the machine after entering the factory, to the comprehensive process of painting and shipping. Each step significantly affects the quality of the maintenance results. In order to ensure the quality of maintenance, various requirements in vibrating screen exciter maintenance are also particularly critical. From bearings to boxes, to gears and other parts, relevant standards and specifications need to be strictly adhered to to ensure that the vibrating screen exciter is maintained during maintenance. Finally, the expected working performance can be achieved.

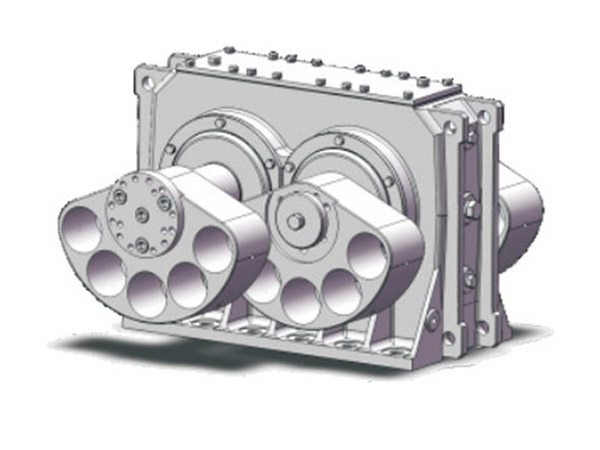

Vibrating screen exciter maintenance

1. Vibrator maintenance process

Take photos and archive the original condition of the machine after entering the factory → Shot blasting → Spray primer → Disassemble the vibrator → Take photos and archive the parts → Clean the parts → Inspect, test and archive → Issue a test report → The salesperson will confirm the damage with the user Form a damage determination confirmation form → formulate a maintenance plan → receive parts → inspect, record and archive → ultrasonic cleaning → assembly → test and record and file → spray paint → ship

2. Vibrator maintenance requirements

- Bearings

It must be replaced during maintenance, and high-quality SKF special bearings for vibrating screens must be selected to ensure that they can withstand high-intensity vibration working environments and maintain long-term stable operation. Careful installation and adjustment work is also essential to ensure the correct installation position and normal working condition of the bearings.

- Sealing

The replacement of seals is an important guarantee for the normal operation of the exciter. When replacing, it is necessary to select high-quality seals that match the original parts to ensure that they can effectively prevent the leakage of lubricating oil or other substances, thereby protecting the internal parts of the exciter from damage.

- Box

Boxes that are cracked, deformed, thread damaged or worn must be replaced; when the box hole and the bearing outer ring installation position are worn and the bearing does not meet the assembly requirements, they must be replaced. The new box should be replaced with high-strength ductile iron QT400-12 material, which has no defects such as slag inclusions, pores, cracks, etc. and has been inspected by ultrasonic to ensure its durability and stability. During the processing of the cabinet, the precision machining process of the CNC machining center should be strictly implemented to ensure the accuracy and stability of the cabinet.

- Axis

During the maintenance process, shaft replacement is a key link to ensure the normal operation of the vibrator. If there are obvious concave and convex marks on the surface of the shaft, the ovality of the bearing position and gear position is ≥0.01mm, and the assembly dimensions of the shaft and the inner ring of the bearing do not meet the requirements, they must be replaced. The replacement shaft is made of alloy structural steel 42CrMo processed by CNC machine tools, which can ensure good strength and wear resistance. During the installation process, ensure that the assembly dimensions of the shaft and the inner ring of the bearing meet the requirements to ensure the operation of the vibrator.

…

For more detailed information about vibrating screen exciter maintenance procedures and maintenance requirements, please click here: https://www.hsd-industry.com/news/vibrating-screen-exciter-maintenance/