Vibrating Screen Exciter Installation Guide

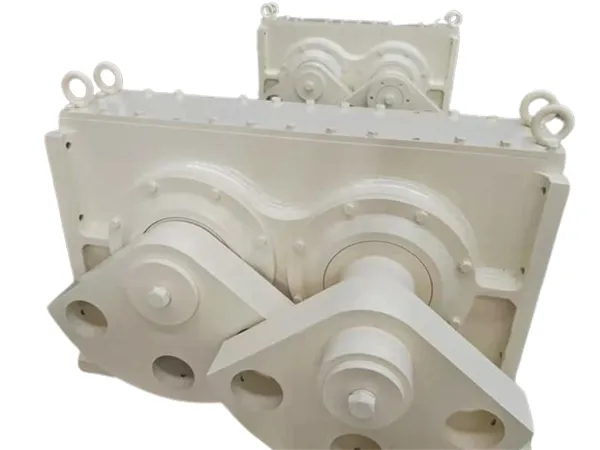

The vibrating screen exciter is a crucial component in screening equipment, responsible for generating the vibratory motion that enables material separation. Proper installation of the exciter is essential for ensuring the optimal performance, longevity, and safety of vibrating screens.

This guide provides step-by-step instructions for the correct installation of various types of screen exciters, covering preparation, alignment, fastening, lubrication, and initial testing. Whether for new equipment setup or replacement of existing exciters, following these guidelines will help reduce downtime and prevent premature wear or mechanical failure.

Vibrating Screen Exciter Installation Guide

Pre-Installation Preparation

Verify Parts:

Confirm you have the correct exciter model and configuration (rotation, mounting type) for the specific screen and position.】

Inspect the exciter for any shipping damage. Report any damage immediately.

Ensure you have the correct quantity, size, grade (typically Grade 8 or Metric 10.9), and length of new mounting bolts, hardened washers, and nuts (if applicable). Never reuse old mounting bolts.

Check if seals, O-rings, or gaskets are required and supplied.

Gather Tools & Equipment:

Calibrated Torque Wrench (appropriately sized for required torque values)

Socket Set and Wrenches (correct sizes for mounting bolts)

Lifting Equipment (crane, hoist, slings, shackles)

Alignment Tools (straight edge, dial indicators, laser alignment tool if connecting drive shafts)

Cleaning Supplies (wire brushes, scrapers, rags, solvent)

Pry Bars (use cautiously)

Anti-Seize Compound (check manufacturer recommendation)

Thread Locking Compound (check manufacturer recommendation, e.g., Loctite)

Lubricant (correct type and grade of oil or grease as specified by the manufacturer)

Measuring Tools (tape measure, feeler gauges)

Manufacturer’s Installation Manual and Screen Drawings

Prepare the Screen:

Thoroughly clean the exciter mounting surface(s) on the screen side box or exciter support beam. Remove all old gasket material, sealant, rust, dirt, grease, and paint. The surface must be clean, dry, and flat.

Inspect the mounting surface for flatness, cracks, or damage. Repair as necessary according to manufacturer specifications.

Clean out the bolt holes. Ensure threads (if tapped) are clean and undamaged. Chase threads with a tap if necessary, but do not remove significant material.

Prepare the Exciter:

Clean the mounting flange(s) of the new exciter.

Verify the correct orientation for installation (e.g., oil level plugs, breathers, rotation direction).

…

More detailed information about the installation guide of the vibrating screen exciter can be found at: https://www.zexciter.com/en/a/news/vibrating-screen-exciter-installation-guide.html