What are the process flows of valve bags?

Valve bags, also known as valve sacks or open-mouth bags with a valve, are commonly used for packaging bulk materials such as cement, fertilizer, grains, and various powdered or granular products. These bags feature a one-way valve that allows for efficient and controlled filling and emptying of the contents.

Valve bag process flows

Bag Manufacturing:

The process begins with the manufacturing of valve bags. These bags are typically made of multi-layer paper, plastic, or a combination of both to provide strength and moisture resistance.

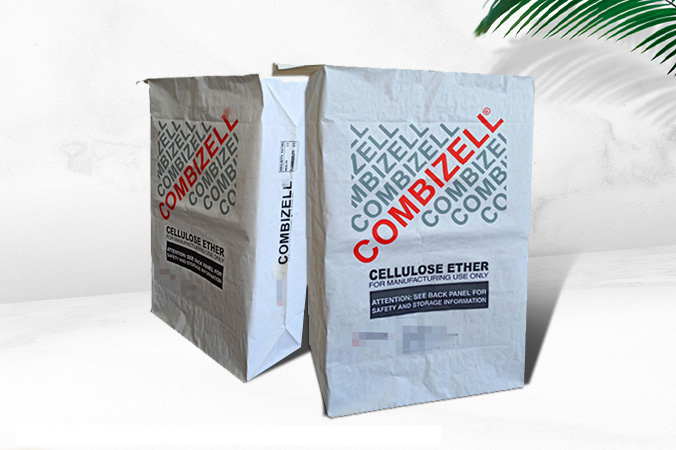

Printing and Labeling (Optional):

If branding, product information, or labels are required on the bags, printing and labeling can be done before they are sent to the filling facility.

Bag Storage:

Valve bags are stored in a clean and dry area until they are ready to be filled with the desired product.

Product Filling:

The product to be packaged is loaded into a hopper or filling machine.

The valve bag is placed onto the filling spout of the machine.

The product flows through the valve into the bag. The one-way valve prevents air from entering the bag during filling, allowing for efficient filling without the need for additional sealing.

Weighing and Dosing (Optional):

In some applications, the filling machine may include a weighing and dosing system to ensure that each bag contains the desired amount of product.

Bag Sealing and Closing:

After filling, the valve bag is carefully removed from the filling spout.

The bag’s valve closes automatically as it is removed from the spout, preventing any product from escaping.

Some valve bags may require additional sealing or stitching to ensure they are properly closed.

…

For more detailed information about the valve bag process flows, please click here: https://www.lyhuatianm.com/products-information/valve-bag-process-flow.html