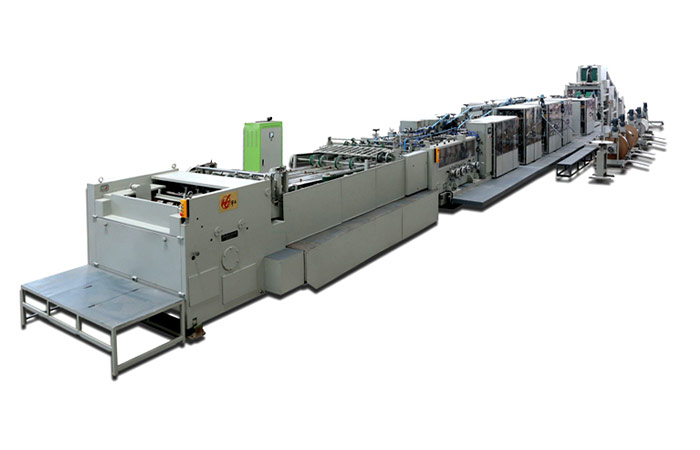

Overall scheme design of paper yarn composite bag square bottom machine

The bottom paste process of traditional paper yarn composite bags mainly adopts the method of artificial bottom paste, which has low production efficiency, uneven specifications and low quality; practice shows that in the case of producing paper bags of the same specification, the bottom paste can be improved compared with manual sewing. 20% capacity, 8% paper saving, 12% cost reduction. In order to solve these problems, the packaging industry urgently needs an automatic bottom paste equipment to reduce labor costs and waste materials and improve efficiency.

Traditional artificial bottom paste is divided into two ways: artificial seam bottom and artificial bottom paste.

The specific steps of artificial bottom sewing are as follows:

(1) Prepare the produced paper tube, use the sewing machine, yarn and glue for sewing the bottom;

(2) The worker dips the yarn in glue and installs it on the sewing machine;

(3) Use a sewing machine to sew one end of the paper tube through glued yarn;

(4) Paste the valve port on the other end of the paper tube and sew it with glued yarn;

(5) Spread out the paper bags sewn at both ends to dry, and complete the seam bottom work of the paper bags.

Traditional artificial bottom paste process:

(1) Workers mark the position of one long indentation, two 45° indentations and two vertical indentations on the paper tube, and manually indent and cut them;

(2) Unfold the bottom of the bag and fold two indentations manually;

…

For more detailed information on the overall design of the paper yarn composite bag square bottom machine, please click to visit:https://www.lyhuatianm.com/products-information/scheme-design-of-paper-yarn-composite-bag-square-bottom-machine.html