How does the plate conveyor work?

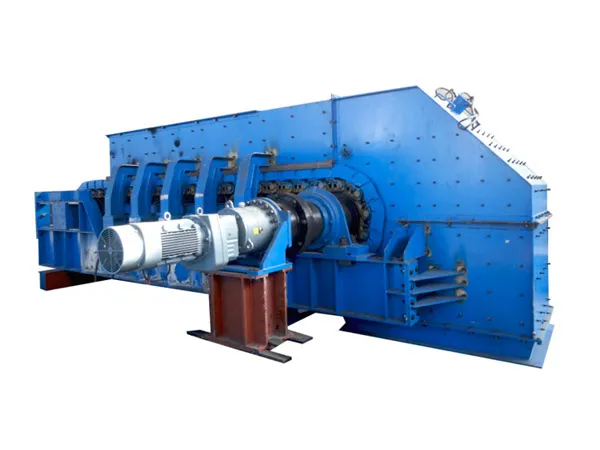

A plate conveyor is a type of conveyor system specifically designed to transport flat, large, or heavy materials, such as metal plates, sheets, or panels, through various stages of a manufacturing or assembly process. Plate conveyors are commonly used in industries like automotive, metalworking, and heavy manufacturing.

Plate conveyor working principle

1. Design and Components:

Conveyor Bed: The conveyor bed is the surface on which the plates or materials are placed. It consists of a series of linked or interconnected plates, often made of steel or other durable materials, forming a continuous, flat surface.

Drive System: The drive system powers the conveyor, typically consisting of an electric motor connected to a gearbox and drive chain or belt. The drive system moves the plates along the conveyor bed.

Rollers or Chains: Underneath the conveyor bed, rollers or chains help to support the weight of the plates and facilitate their smooth movement along the conveyor.

Guides and Sidewalls: These components ensure that the plates remain aligned on the conveyor bed and prevent them from sliding off during transport.

Control System: The conveyor’s operation is managed by a control system that regulates the speed, direction, and timing of the conveyor’s movement. This system may include sensors, switches, and other control devices.

2. Operation Process:

Loading the Plates:

Plates or flat materials are loaded onto the conveyor bed. This can be done manually, with the help of a crane, or through an automated feeding system, depending on the size and weight of the plates.

Conveyor Movement:

Once the plates are loaded, the conveyor begins moving them along the length of the system. The movement can be continuous or indexed (moving in steps), depending on the application.

Transportation of Materials:

The plates are transported from one end of the conveyor to the other. Along the way, they might pass through different workstations where various operations like cutting, welding, coating, or inspection take place.

Stopping and Positioning:

The conveyor can be programmed to stop at specific intervals, allowing for precise positioning of the plates for processing. For example, the conveyor might stop to allow a robotic arm to perform a welding operation, then continue moving once the task is completed.

Unloading the Plates:

At the end of the conveyor, the plates are unloaded. This can be done manually or through an automated system, such as a robotic arm or another conveyor that takes the plates to the next stage of production.

3. Types of Plate Conveyors:

Flat Plate Conveyors: These are the most basic type, featuring a flat, continuous surface made of metal plates. They are ideal for transporting heavy and large items.

Slat Plate Conveyors: Slat conveyors have individual slats (plates) attached to chains. These are often used for handling large, heavy, or awkwardly shaped items that need to be kept in a stable position during transport.

…

For more detailed information about the working principle of plate conveyor, please click here: https://www.zymining.com/en/a/news/plate-conveyor-working-principle.html