Maintenance of hydraulic excavator slewing bearing

Hydraulic excavators generally use single-row four-point contact ball-type internal gear slewing bearings. During the excavator operation, the excavator slewing bearing bears complex loads such as axial force, radial force and tipping moment, and its reasonable maintenance is very important. The maintenance of the excavator slewing bearing mainly includes the lubrication and cleaning of the raceway and the inner gear ring, the maintenance of the inner and outer oil seals, and the maintenance of the fastening bolts. Now from these seven aspects will be described in detail.

1. Lubrication of raceways

Slewing bearing rolling elements and raceways are easy to damage and fail, and their failure rate is high. During the use of the excavator, adding grease to the raceway can reduce the friction and wear among the rolling elements, the raceway and the spacer. The space of the raceway cavity is small, and the resistance to filling grease is large, so manual filling with a manual grease gun is required. The lubricating oil nozzles of the slewing bearing raceway are generally distributed at the position of the outer wall of the slewing bearing.

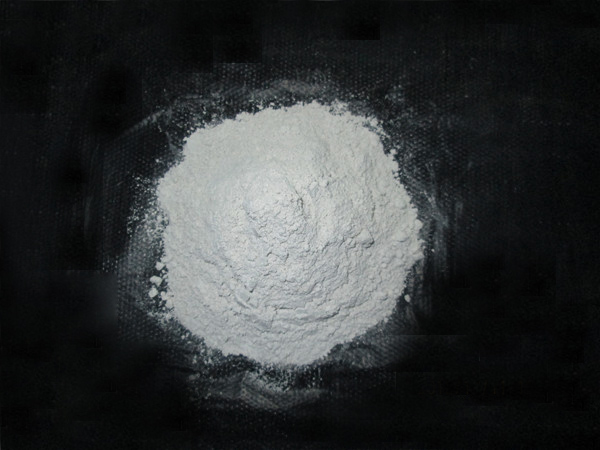

The raceway cavity is generally lubricated with 2# file-based grease, and the grease filling cycle is generally 100h. Under special working conditions such as high dust, high temperature, and continuous operation, the filling cycle should be appropriately shortened. When adding grease, it is necessary to rotate the slewing bearing, and add it about once every 15°~25°. When filling, pay attention to observe the outer sealing ring of the slewing bearing. When you see grease seeping out from the outer sealing ring, stop filling.

When the raceway cavity is filled with grease, bad filling methods such as “refueling in static state” and “single-point oiling” should be avoided, because the above-mentioned bad filling methods will cause local oil leakage of the slewing bearing, and even cause the oil seal of the slewing bearing to become permanent. Damaged, resulting in grease loss, impurity intrusion, and accelerated raceway wear. Be careful not to mix different types of grease to avoid premature failure.

When replacing the seriously deteriorated grease in the raceway of the slewing bearing, the slewing bearing should be rotated slowly and uniformly while filling, so that the grease can be filled evenly in the raceway. This process can not be rushed, it needs to be done step by step to complete the metabolism of grease.

2. Maintenance of the gear meshing area

Open the metal cover on the base of the slewing platform to observe the lubrication and wear of the ring gear of the slewing bearing and the pinion of the slewing motor reducer. A rubber pad should be placed under the metal cover and fastened with bolts. If the bolts are loose or the rubber gasket fails, water will seep from the metal cover into the lubricating cavity (oil collecting pan) of the rotating inner gear ring, causing premature failure of the grease, reduced lubrication effect, and increased gear wear and corrosion.

The method of replacing the grease in the lubricating cavity of the ring gear is as follows: first, use the working device to support the excavator, and the operator goes under the crawler frame of the excavator and opens the metal cover; secondly, drop the excavator to the ground and start the excavator Do the rotating action for about 10 laps, and the failed grease can be exhausted. The lubricating cavity of the ring gear of the slewing bearing is also filled with 2# file base grease. The replacement cycle is generally 2000h, and the filling amount should be determined according to the model of the excavator.

…

Details can be accessed by clicking here:https://www.excavatorbearing.com/a/bearing-knowledge/maintenance-of-excavator-slewing-bearing.html