Benefits of Using a High-Frequency Vibrating Screen Exciter in Industrial Screening

In industries such as mining, quarrying, construction materials, and chemical processing, efficient material screening is a critical step that directly affects product quality, production capacity, and operating costs. As material specifications become more demanding—especially for fine and ultra-fine particles—traditional low-frequency screening methods often struggle to deliver stable and accurate results.

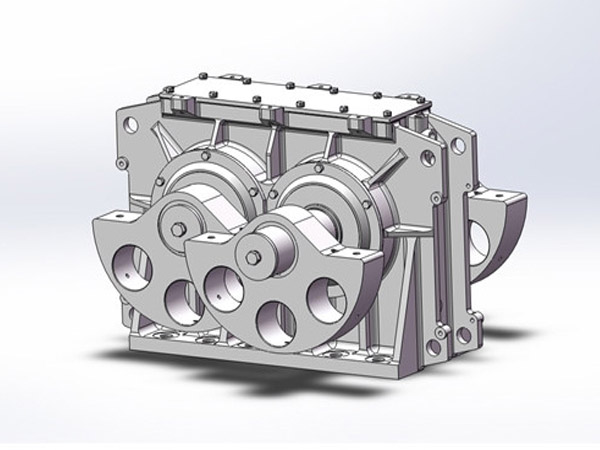

This is where a high-frequency vibrating screen exciter becomes a key performance-enhancing component. By providing controlled, high-speed vibration, it significantly improves screening accuracy, reduces downtime, and increases overall plant efficiency. Below, we explore the major advantages of using a high-frequency vibrating screen exciter in modern industrial applications.

Benefits of Using a High-Frequency Vibrating Screen Exciter

1. Significantly Improved Screening Efficiency

One of the most notable benefits of a high-frequency vibrating screen exciter is its ability to dramatically enhance screening efficiency. The rapid vibration frequency creates intense particle movement across the screen surface, allowing fine materials to pass through the mesh more easily.

Compared with conventional exciters, high-frequency units are especially effective when handling:

Fine sand and mineral concentrates

Slurries and wet materials

Ultra-fine powders used in chemical or industrial processing

By accelerating particle separation, plants can achieve higher throughput without sacrificing accuracy, resulting in more consistent product grading and improved downstream performance.

2. Better Material Stratification and Reduced Blinding

High-frequency vibration promotes effective material stratification. Smaller particles are driven downward toward the screen openings, while larger particles remain on the surface and move toward discharge. This continuous separation process minimizes material layering and reduces common issues such as screen blinding and clogging.

…

For more detailed information on the advantages of high-frequency vibrating screen exciters in industrial screening, please click to visit:https://www.hsd-industry.com/news/benefits-of-using-a-high-frequency-vibrating-screen-exciter/