Turntable Bearing Size Collection

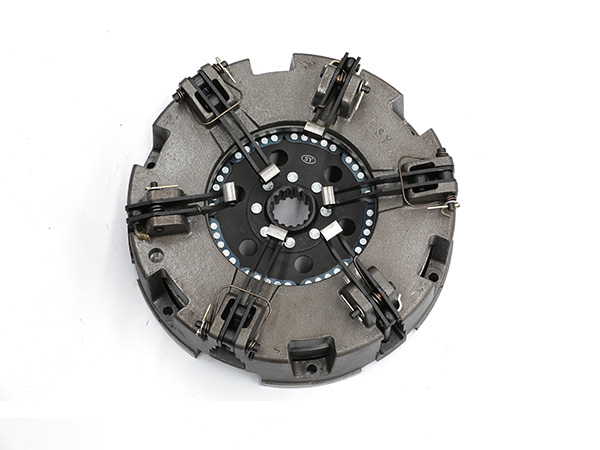

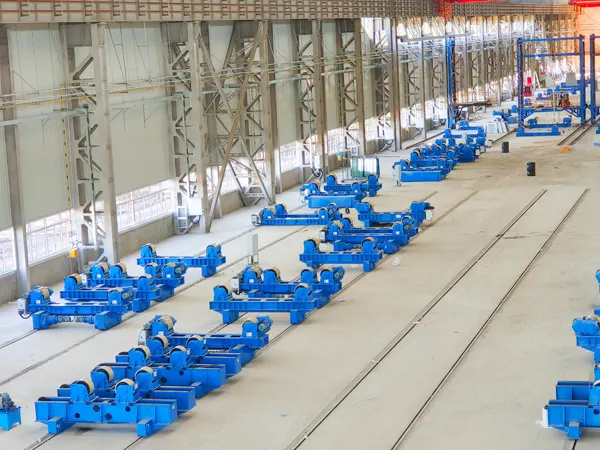

A turntable bearing, also known as a lazy Susan bearing, is a specialized type of rotational bearing that allows for smooth and controlled rotation of a platform or turntable. These bearings are commonly used in various applications where the ability to rotate objects is required, such as in lazy Susans, swiveling chairs, rotating displays, industrial machinery, and other systems. The design of turntable bearings allows for low-friction, precise rotation, and they come in different configurations to meet specific needs.

The size of a turntable bearing, often referred to as a lazy Susan bearing, is typically specified by its diameter. Turntable bearings come in various sizes to accommodate different applications. The size is usually given in inches or millimeters, representing the diameter of the circular raceway where the turntable rotates.

The collection of turntable bearing sizes

4 Inches (100 mm): Common for small to medium-sized applications, such as rotating displays, cabinets, or light-duty turntables.

6 Inches (150 mm): Slightly larger than the 4-inch size, suitable for applications requiring a bit more load capacity.

8 Inches (200 mm): Widely used for various purposes, including rotating tabletops, kitchen cabinets, and other medium-duty applications.

12 Inches (300 mm): Larger size suitable for heavier applications, such as industrial turntables, display platforms, or rotating stages.

…

For more detailed information about the dimensions of turntable bearings, please click here: https://www.prsbearings.com/a/news/turntable-bearing-size.html