How does graphite felt performs as insulation in vacuum furnaces?

Graphite felt is a widely used and highly effective insulation material in vacuum furnaces, particularly for high-temperature applications. Here’s a breakdown of its characteristics, advantages, and considerations.

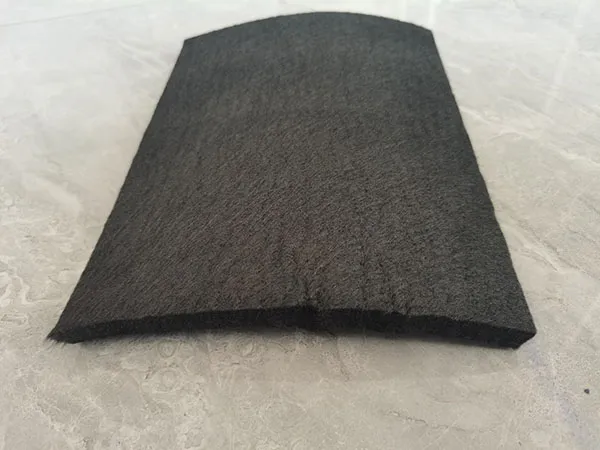

What is Graphite Felt?

Graphite felt is a fibrous material made from carbon fibers that have been subjected to high-temperature graphitization processes. It can be manufactured from various precursor materials like polyacrylonitrile (PAN) or rayon. The “felt” structure, often needle-punched, gives it a low density and high porosity, which are crucial for its insulating properties. There are typically two forms:

Soft Graphite Felt: Flexible and can be shaped around furnace walls.

Rigid Graphite Felt (or cured graphite felt): Made by impregnating soft felt with resin, then curing and graphitizing it to create self-supporting shapes.

How it Performs as Insulation in Vacuum Furnaces:

Graphite felt excels as insulation in vacuum furnaces due to several key properties:

Excellent Thermal Insulation: Its low density and porous, fibrous structure create numerous small air gaps (or vacuum gaps in a vacuum furnace) that significantly impede heat transfer by conduction. This results in very low thermal conductivity, especially at high temperatures. Compared to graphite board, graphite felt has significantly lower thermal conductivity, leading to less heat loss.

High-Temperature Stability: Graphite is an allotrope of carbon, and in a vacuum or inert atmosphere, it can withstand extremely high temperatures (up to 3000°C or even higher) without melting or significant degradation. It even exhibits an increase in strength as temperatures rise.

Low Thermal Mass: Its lightweight nature means it absorbs less heat, allowing the furnace to reach operating temperatures faster and cool down more quickly, contributing to energy efficiency and shorter cycle times.

Good Thermal Shock Resistance: Graphite felt can withstand rapid temperature changes without cracking or deforming, maintaining its structural integrity in demanding furnace environments.

Chemical Inertness: In non-oxidizing atmospheres (vacuum or inert gas), graphite is highly resistant to many chemicals and corrosive media, which is crucial in preventing contamination of processed materials.

Ease of Maintenance and Installation: Soft graphite felt is relatively easy to cut, shape, and replace, making repairs and modifications simpler compared to rigid board materials. It can also be maneuvered around mounting points and nozzles.

Advantages of Graphite Felt Insulation:

Energy Efficiency: Low thermal conductivity minimizes heat loss, reducing energy consumption and operating costs.

Faster Cycle Times: Low thermal mass allows for quicker heating and cooling, improving productivity.

…

For more details on how does graphite felt performs as insulation in vacuum furnaces, please click here:https://www.czgraphite.com/a/news/graphite-felt-for-vacuum-furnace-insulation.html