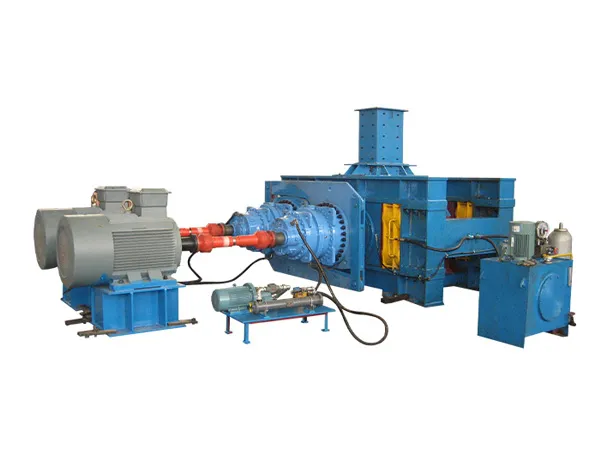

High pressure grinding roller inspection and maintenance

High-pressure grinding rolls is mainly used in the ore industry and is also a type of crusher. As the main equipment for crushing in the ore industry, since it is the main equipment, it will be used very frequently. All machines are inseparable from daily maintenance and overhaul. Correct maintenance and overhaul can increase the service life of the machine, and early overhaul can detect problems early, so that small problems will not become bigger, affecting normal work and causing accidents.

Common fault inspection and repair of high-pressure grinding rolls

1. If the lubrication system finds that there is no grease overflow from the labyrinth seal of the bearing seat, the following reasons may be the case:

① lack of oil;

② pipeline failure;

③ grease pump is broken. If the color and properties of the oil flowing out of the oil drain port of the non-loaded bearing seat are found to have changed, it may be that cooling water or other foreign matter has been mixed into the lubricating grease.

2. The movable roller moves irregularly in the horizontal direction. Generally, the nitrogen accumulator pressure is insufficient or damaged.

3. The hydraulic oil temperature is high. It may be: serious internal leakage in the system or the pump has been running for too long, and the hydraulic system needs to be checked.

4. The roller gap is too large. There may be the following reasons:

① Severe wear on the roller surface;

② No pressure;

③ There is material accumulation between the rollers. It needs to be handled as appropriate.

5. The roller gap is too small. It may be that there is a problem with the size of the gap block, or the position of the displacement sensor is set incorrectly.

6. The roller is stuck. It may be that there is foreign matter between the rollers, or there is too much material stored between the rollers when starting.

7. The roller does not rotate. The reasons include:

① Motor failure;

② Reducer failure.

8. The roller surface temperature is too high. It may be that the feed temperature is too high. Measures should be taken to control the upstream raw material temperature, otherwise it will affect the wear resistance of the roller surface and accelerate wear.

9. The bearing temperature is too high. The reasons include:

…

For more detailed information on the inspection and maintenance of high pressure grinding roller, please click here:https://www.zymining.com/en/a/news/high-pressure-grinding-rolls-inspection.html