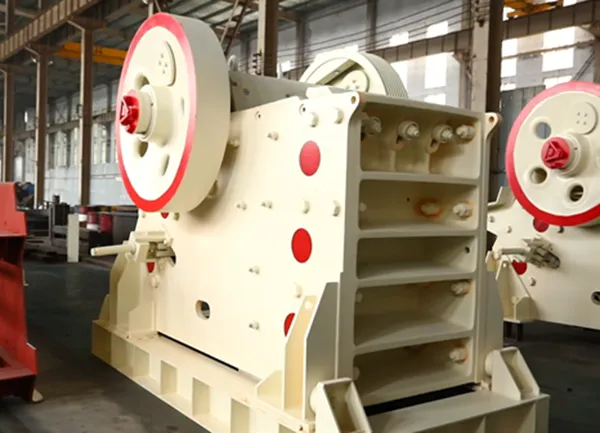

How to reduce the noise of jaw crusher

Reducing the noise generated by a jaw crusher is crucial for worker safety, environmental regulations, and community relations. Jaw crushers are inherently noisy due to the high-impact nature of rock crushing. Here’s a breakdown of methods to reduce jaw crusher noise, categorized for clarity.

How To Reduce The Noise of Jaw Crusher

1. Source Control (Modifying the Crusher/Process):

Optimize Feed:

Consistent Feed Rate: Avoid large, sudden drops of material. A steady, choked feed (keeping the crushing chamber relatively full) can sometimes dampen impact noise slightly, although it might increase overall operational noise. Experiment to find the optimal balance.

Scalping: Pre-screen the feed material to remove fines that don’t need crushing. This reduces the amount of material going through and can lower noise.

Proper Maintenance:

Lubrication: Ensure all bearings and moving parts are adequately lubricated to reduce mechanical noise.

Tighten Fasteners: Loose bolts and components can vibrate excessively, creating noise. Regularly check and tighten all fasteners.

Replace Worn Parts: Worn jaw plates, bearings, and drive components can operate less efficiently and generate more noise. Replace them promptly.

Balance Rotating Parts: Ensure flywheels and drive components are properly balanced to minimize vibration.

Operational Settings: Ensure the crusher is operating at the recommended speed and Closed Side Setting (CSS) for the material being processed. Incorrect settings can increase stress and noise.

2. Path Control (Blocking or Absorbing Noise Transmission):

Enclosures:

Full Enclosure: Build a soundproof or sound-reducing enclosure around the crusher itself. This is often the most effective method but also the most expensive.

Considerations include:

Materials: Use heavy materials with good sound transmission loss (e.g., concrete, thick steel) combined with internal sound absorption materials (e.g., mineral wool, acoustic foam).

Ventilation: Enclosures require adequate ventilation systems, which themselves need silencers to prevent noise leakage.

…

For more detailed information on how to reduce the noise of jaw crusher, please click here: https://www.yd-crusher.com/a/news/how-to-reduce-the-noise-of-jaw-crusher.html