Common failures and solutions of slewing bearings

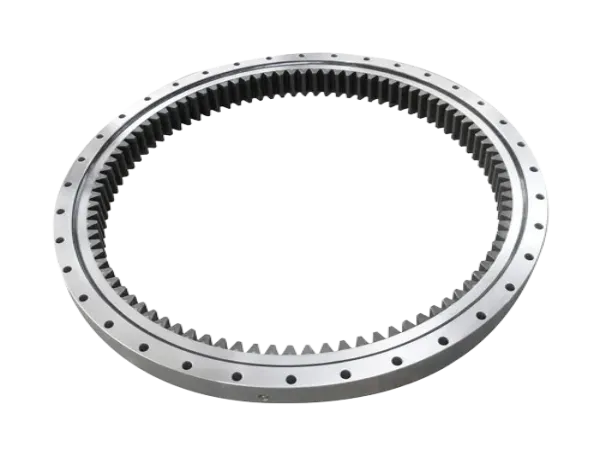

Slewing bearing as a common mechanical parts in the current industrial machinery, because it has good performance advantages to improve the efficiency of industrial production is widely used. So in the long-term use of the process will inevitably appear a lot of faults, the following is a summary of common failure phenomena, cause analysis and solutions:

Common failures and solutions of slewing bearings:

1. Rattling:

Mainly manifested in the rotation of the “thump” sound or continuous friction sound, metal impact sound. The reason for the noise may swim raceway surface wear, insufficient lubrication leading to dry friction, cage fracture, rolling body collision, excessive clearance leading to shock vibration. The solution needs to be disassembled and inspected first to ensure that the condition of the rolling body. Re-lubrication optimization to avoid dry friction. Adjust the clearance (0.05~0.15mm). If the cage is broken to replace the cage.

2. Rotating stall:

The main manifestation of the equipment rotary inflexible with obvious obstacles or motor overload alarm. Usually the reasons are mounting surface flatness > 0.2mm / m, raceway into the foreign body, rotating parts were extruded, negative clearance set wrong. The solution needs to repair the mounting surface first, and then clean and seal upgrades after recalibration of the negative clearance.

3. Grease leakage:

Mainly manifested in the seal out of grease oozing. The causes of this problem are usually worn seals, grease oxidization at high temperatures after thinning, equipment tilt angle is too large. The solution is to modify the sealing system and replace the grease while optimizing the grease injection cycle.

…

More detailed information about the common failures and solutions of slewing bearings can be found by visiting: https://www.mcslewingbearings.com/a/news/common-failures-and-solutions-of-slewing-bearings.html