Briquetting Machine: A Dual Weapon of Environmental Protection and Efficiency

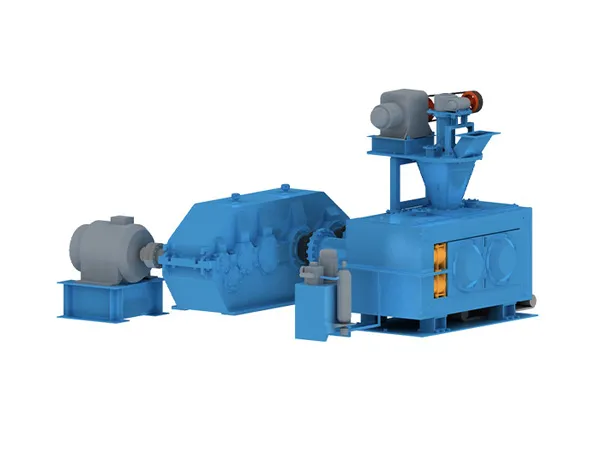

A briquetting machine is a device that forms solid block products from powdered or granular materials under pressure. It is widely used in industries such as coal, biomass fuel, metal waste and chemical raw materials. With the increasingly stringent environmental regulations and the emphasis on resource recycling, briquetting machines are playing an increasingly important role in the field of waste treatment and resource recycling.

briquetting machine: A dual weapon of environmental protection and efficiency

In today’s era of increasing environmental awareness, briquetting machines, as a device that converts waste into usable resources, are being favored by more and more industries. This article will explore in depth the working principle, technical parameters, application fields and market prospects of briquetting machines to provide users with comprehensive technical insights.

1. Working principle of briquetting machine

The working principle of briquetting machine mainly includes the following steps:

Material supply: The raw materials are fed into the feeding device of the briquetting machine by the material supply system. Some briquetting machines are also equipped with pretreatment equipment, such as mixers or blenders, to ensure uniform mixing and pretreatment of the materials.

Prepressing: The material enters the prepressing chamber from the feeding device, and the material is prepressed into particles of a certain shape and size by the rotation of the prepressing roller and appropriate pressure.

Main pressing: The pre-pressed particles enter the main pressing chamber, which is usually equipped with a piston or mold. By applying greater pressure, the particles are further compressed, the gaps in the material are filled, and the bonding force between the particles is enhanced.

Discharging: After the briquetting is completed, the roller or mold is opened, and the formed block material is pushed out of the briquetting machine for subsequent processing, such as drying, cooling or packaging.

2. Technical parameters of briquetting machines

The technical parameters of briquetting machines vary depending on their type and purpose. For example, the performance and relevant technical parameters of straw briquetting machines are as follows:

…

More information about briquetting machine functions can be found at: https://www.zymining.com/en/a/news/briquetting-machine-function.html