What are the common faults of high pressure grinding rolls and how to solve them

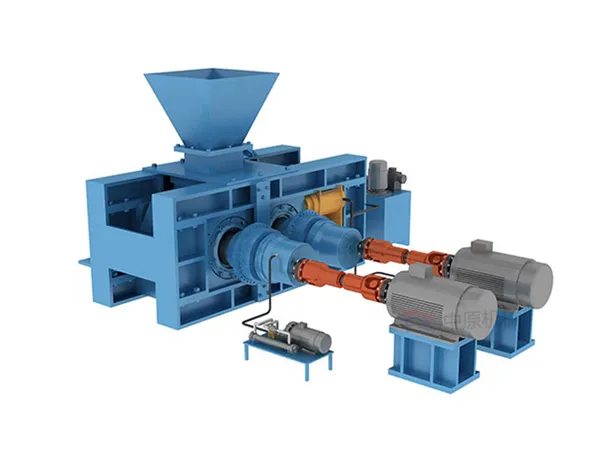

The high pressure grinding rolls is composed of two rollers, one of which is fixed and the other can slide horizontally. The material is continuously fed from the top and passes through the gap between the rollers. The movable roller is pressurized by hydraulic pressure, the material is crushed by pressure, and is pressed into cakes and falls out of the machine.

High pressure grinding rolls may encounter a variety of common faults during operation. These faults and their solutions can be summarized as follows:

1. Abnormal vibration

Fault causes:

Uneven material size: Uneven material size will cause the extrusion force of the equipment to be unbalanced, causing vibration.

Severe wear of the scraper: The scraper cannot effectively shovel the material after wear, causing the roller to squeeze the material sometimes and sometimes not, causing vibration.

Too hard material: Too hard material may cause deformation and wear of the grinding roller and grinding ring, thereby aggravating vibration.

Fan problem: The fan blades of the high-pressure suspended shaft grinding fan accumulate too much powder or wear, causing unbalanced rotation of the fan blades.

Loose anchor bolts: After the equipment has been used for a period of time, the anchor bolts may loosen due to vibration or installation reasons.

Solution:

Adjust the particle size of the material and try to make it uniform.

Regularly check and replace worn scrapers.

Avoid processing of too hard materials, regularly check and replace grinding rollers and grinding rings, and remove metal debris from the material.

Remove the accumulated powder on the fan blades in time, and replace them in time if they are worn.

Pay attention to the tightness of the anchor bolts during daily maintenance. Tighten them in time if they are loose.

2. Powder discharge problem

Cause of failure:

Wear of shovel blade: Wear of shovel blade leads to reduced powder discharge.

Powder lock is not adjusted properly: The seal of powder lock is not tight, resulting in powder back-sucking.

Solution:

Check and replace worn shovel blades regularly.

…

For more detailed information about common faults and solutions of high pressure grinding rolls, please click to visit: https://www.zymining.com/en/a/news/common-faults-and-solutions-of-high-pressure-grinding-rolls.html