What should you pay attention to when using a welding turntable?

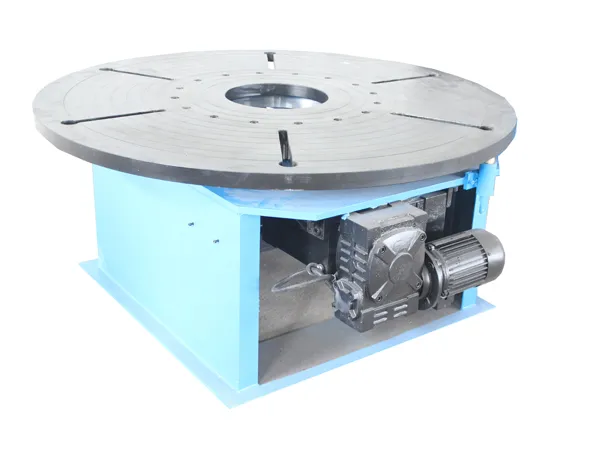

A welding turntable, also known as a welding positioner or welding rotary table, is a specialized piece of equipment used in welding applications to rotate the workpiece around a horizontal or vertical axis. This rotation capability allows welders to position the workpiece at the optimal angle for welding, making the welding process more efficient and precise. Welding turntables are commonly used in industries such as manufacturing, construction, and automotive to weld circular or cylindrical objects, pipes, tanks, and other components.Here are some key features and considerations when using a welding turntable.

Features of a Welding Turntable

Rotation Control: Welding turntables can rotate the workpiece continuously or in specific increments. The rotation speed can often be controlled to match the welding process requirements.

Load Capacity: Turntables come in various sizes and weight capacities. It’s important to choose a turntable that can support the weight of the workpiece and any fixtures securely.

Adjustable Angle: Some turntables allow the tilting of the workpiece to achieve specific welding angles, enabling welding in various positions without manual manipulation.

Chuck or Fixture: Turntables often come with chucks or fixtures that secure the workpiece during rotation, ensuring stability and accuracy during welding.

Variable Speed: Adjustable rotation speed is crucial for different welding applications. Some welding processes require slower rotation for precise welding, while others benefit from faster rotation for efficiency.

Remote Control: Many modern turntables come with remote control features, allowing the operator to adjust rotation speed and direction without being physically close to the equipment.

Considerations when Using a Welding Turntable:

Safety: Always follow safety protocols and guidelines when operating welding equipment. Ensure that the turntable is stable, and the workpiece is securely fastened to prevent accidents.

Welding Process: Different welding processes (e.g., MIG, TIG, or submerged arc welding) have specific requirements regarding rotation speed and angles. Consult welding procedure specifications (WPS) to set the turntable correctly.

…

For more detailed information about the precautions for using welding turntables, please click here: https://www.bota-weld.com/en/a/news/considerations-for-using-welding-turntable.html