Introduce the square bottom machine in detail

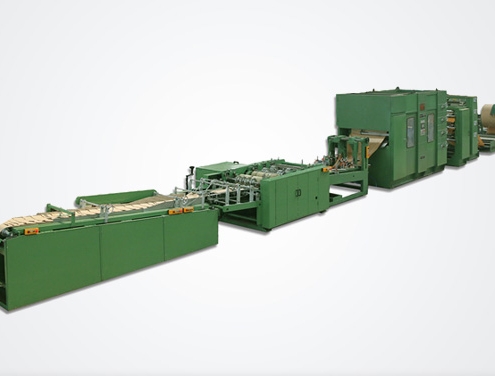

A square bottom machine, also known as a square bottom bag making machine, is a type of packaging machine that is used to produce square bottom bags. These bags are commonly used for packaging products such as rice, flour, and other food products. The bags are characterized by their square bottom, which provides a stable base that allows the bags to stand upright, making them easy to fill and store.

The square bottom machine works by feeding a flat roll of plastic material, known as a film, into the machine. The film is then heat sealed along its sides to form the bottom of the bag. The film is then folded and heat sealed along the bottom to create the square shape. The top of the bag is then sealed and cut to the desired length, completing the bag making process.

Square bottom machines can be designed for different types of films, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE), and can be configured for different bag sizes and shapes. Some square bottom machines also feature additional functions, such as printing, gusseting, and automatic bag loading, to increase their versatility and efficiency.

In terms of operation, square bottom machines are typically operated by a single operator, who is responsible for feeding the film into the machine and monitoring the bag making process. Some machines also feature automatic systems that can detect when a bag is not properly formed, and will stop the machine to allow the operator to fix the problem.

In conclusion, square bottom machines are an essential tool in the packaging industry, providing a reliable and efficient means of producing square bottom bags. With their ability to handle different types of films and produce bags of different sizes and shapes, they are a versatile and cost-effective solution for a wide range of packaging needs.

For more detailed information about the introduction of the square bottom machine, please click to visit:https://www.lyhuatianm.com/square-bottom-machine